In a saturated market, a firm needs a product that stands out. Good packaging may grab a consumer’s attention. How can firms create high-quality, identifiable packaging? High-quality packaging structure design helps make successful products. Follow us to know how.>

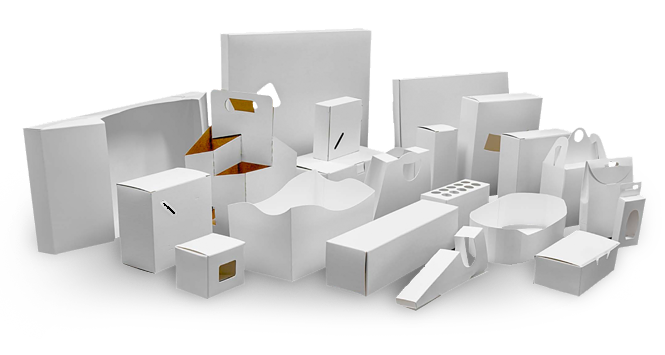

What is packaging structure?

A structural package design is a three-dimensional package that employs creativity, functional simplicity, and industrial design. They gather to produce a user experience that is both memorable and pleasurable.

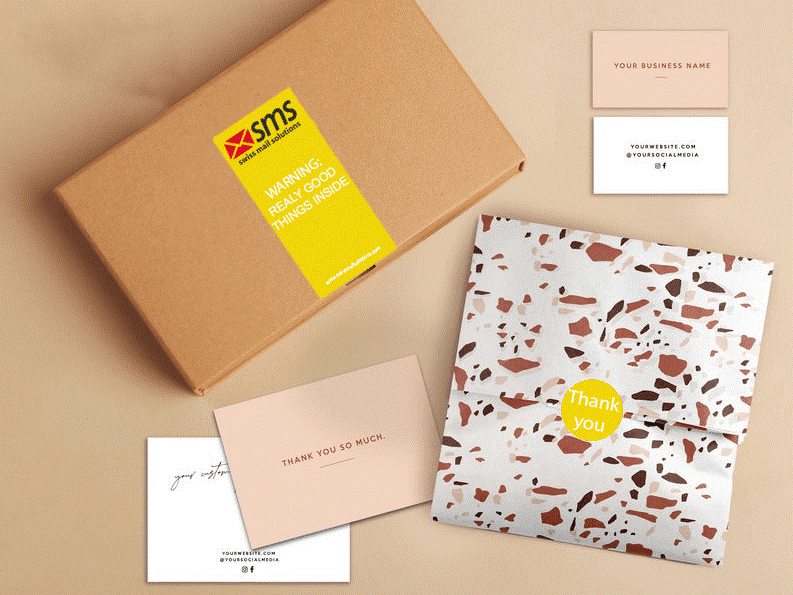

Your product’s structural package design should make it stand out on store shelves. It also increases the value of your brand, and provide a memorable unwrapping experience for the consumer. It should also reflect your brand and the values it upholds. It is possible to get excellent results by developing a bespoke package design rather than relying on a structural design that is mass-produced.

Packaging basic structure

The customer forms their first impression of the product and the brand as a whole based on the packaging. It is imperative that you think about more than just the forms and colors of the packaging. Exactly when you are considering how to make it more attractive to customers. When it comes to the process of designing packaging, structural design is an essential component.

The design of your product’s packaging should accurately portray your brand and the values it upholds, make your product stand out on store shelves. It increases the value of your brand, and provide the end user with a memorable experience when they first open the package.

Imagine that you are at the pharmacy store in your neighborhood looking for shampoo. You always purchase the same brand, but this time you see something that catches your eye. A different brand of shampoo. Since it is created with the exact same components as the other versions.

Think about it, what differentiates this one from the rest? Since it is stored in a more superior container, one would expect it to function more effectively, right? It’s possible that it does, but the packaging that this shampoo comes in is probably the reason you’ve decided to switch to a different brand instead.

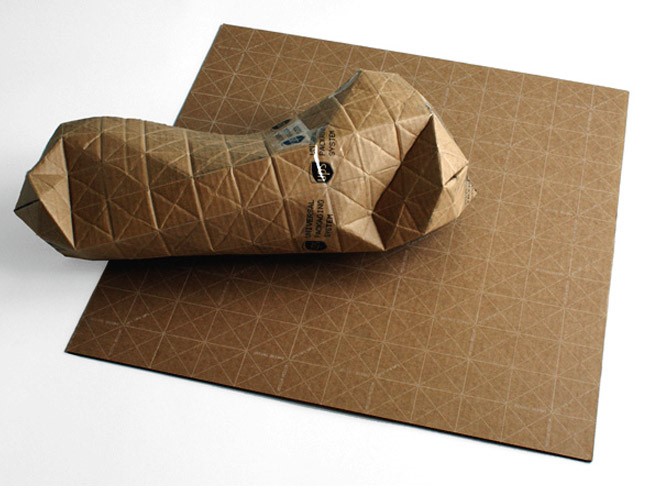

Universal

It appears that a box is either too large or too small, so industrial designer Patrick Sung devised the Universal Packaging System. This packaging also known as UPACKS, which consists of flat sheets made of recyclable corrugated cardboard.

Because of the patterns, it is simple to fold the material so that it may fit into practically any shape. It is preserving its structural stiffness and keeping the contents safe.

Related Article: Packaging Design; The Most Important Part Of Marketing

Holder

The joy of eating ice cream is the ideal gift for everyone throughout any of the four seasons. The joy and contentment that come from sharing an ice cream cone with your loved ones are immeasurable. A scoop of ice cream in a waffle cone is one of those commodities that is believed to sustain cash flow and sell in significant amounts on a regular basis.

Because of the growing demand for ice cream, the packaging sector is seeing an increase in the number of customers looking for ice cream cone holders. These bespoke boxes are portable and easy to move from place to place. The characteristics of ice cream cone holder boxes are a topic of intense interest to establishments that sell ice cream.

The way ice cream cookies are placed appropriately on the crates of holding boxes demonstrates the elegance with which the utility of these boxes in food can be noticed. In order to fit the various sizes of cone biscuits, these cone holders have been separated into equal pieces.

Related Article: Packaging Types; Everything You Want To Know

Dispenser

Cardboard boxes that are designed so as to make them ideal for dispensing a wide range of products are commonly referred to as dispenser boxes. Dispenser boxes often have an easy to tear perforated opening that opens to form a ledge. The products packed inside pour out from this opening for easy dispensing.

Combination

The collaboration of a talented and dedicated team is required in order to develop packaging for a new product that is both effective and impactful. Members of this team may include brand experts, marketers, packaging engineers, creative designers, and print vendors. These are just a few of their potential roles.

You will need a team that has substantial experience as well as considerable skill in both package engineering and creative design. Its because of finding a solution for your product’s packaging that will simultaneously protect it, exhibit it, and market it.

Carrier

The joy of eating ice cream is the ideal gift for everyone during any of the four seasons. The joy and contentment that come from sharing an ice cream cone with your loved ones are immeasurable. A scoop of ice cream in a waffle cone is one of those commodities that is believed to sustain cash flow and sell in significant amounts on a regular basis.

Because of the growing demand for ice cream, the packaging sector is seeing an increase in the number of customers looking for ice cream cone holders. These bespoke boxes are portable and easy to move from place to place. The characteristics of ice cream cone holder boxes are a topic of intense interest to establishments that sell ice cream.

The way ice cream cookies are placed appropriately on the crates of holding boxes demonstrates the elegance with which the utility of these boxes in food can be noticed. In order to fit the various sizes of cone biscuits, these cone holders have been separated into equal pieces.

Window carton

The actual product is often concealed inside the traditional packaging; however, contemporary package designers are working to overturn this paradigm and show the product within the box itself. Window packaging refers to the practice of creating a display area inside the package for the purpose of drawing the attention of potential customers.

The product packaging must have an increased focus on straightforwardness, authenticity, and significance. The first step in contacting customers should always be paying attention to the packaging. If you want your product to stand out from others of its kind, it must not only be of high quality but also come in impressive packaging.

Display Box

In the world of retail, an eye-catching retail packaging solution that is meant to increase the appearance of items on a shop counter is known as a retail display box. It is made out of a durable cardboard box that has been printed with colorful images and advertising material, as well as an integrated display stand that allows buyers to view the product that is being sold.

Display Rack

We have a talented graphic designer on staff that can assist customers in the production of various point-of-purchase (P.O.P.) display racks that include vibrant and imaginative graphic printing artworks. This product may be manufactured using a wide variety of materials, including hard board, foam board, pp board, aluminum, wood, and whatever building material there is.

Our most advanced and high-end machines are capable of doing so. We are able to offer any type of informational display board as well as movie advertising board stands, in addition to display racks.

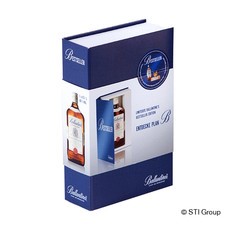

Book shaped

The best-selling publication published by Ballantine’s has packaging in the form of an actual book, in line with the spirit of the publication. The high-quality gift packaging consists of a tray made out of folded components of corrugated board, a traditional book banderole that communicates information about the goods, and a book spine that keeps everything in place.

At the point of sale, matched presentations are achieved via the use of pallet displays that take the form of book shelves and have the capacity to hold either 48 or 64 “books.”

House shaped

The house-shaped gift box offers a one-of-a-kind presentation for all of your items and presents. A stunning quilted embossed design can be seen on the premium paper, which is both thick and of great quality.

Check out our assortment of home gift boxes for the absolute finest in everything one-of-a-kind or bespoke. box made of cardboard in the form of a home, available in a few different colors. Stickers provide another opportunity for personalizing the cardboard home.

Diamond

Diamond Packaging is a worldwide industry leader that has been accredited by WBENC and specializes in producing creative and sustainable packaging solutions. The company was established in 1911. Diamond develops and produces paperboard and plastic folding cartons, counter-top displays, and blister cards by using cutting-edge technology in their production processes.

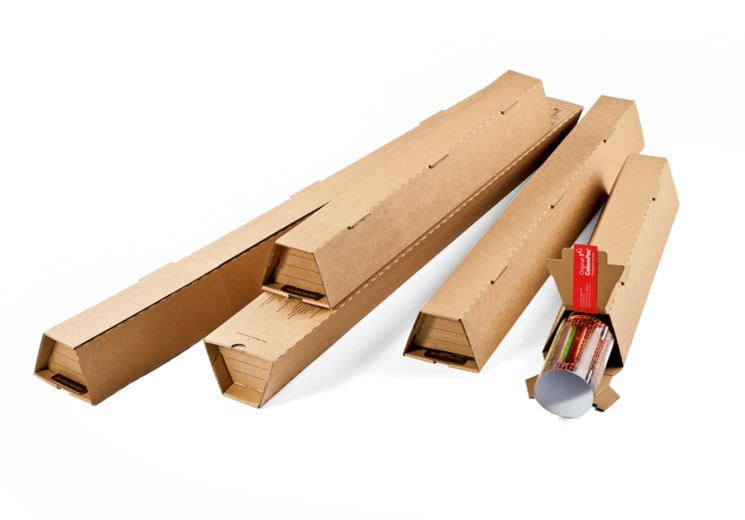

Triangular

A Montessori classroom will have a fascinating wooden box in the shape of a triangle called the Triangular Box. This box is located in the sensory area of the classroom. The contents of this box are as follows: one large equilateral grey triangle, two right-angled green triangles, three yellow obtuse triangles, and four red equilateral triangles.

Trapezoidal box

When it comes to shipping posters, plans, and maps, trapezoid and plan boxes are your best bet. The self-adhesive seal allows for significant time savings. In addition, the corner and edge protectors that are included with this cardboard box give it an extra layer of protection while it is being transported.

Hanging box

When it comes to achieving your sales objectives, making sure that the printed hanging display packaging for your retail goods is just perfect may make all the difference in the world. The retail package printers at Corcoran Printing collaborate with customers to provide the most effective display options for their clients’ wares in retail stores. Product packaging with hang tabs and hanging panels may be excellent options for various types of hanging product display requirements.

They are an excellent choice for enhancing the visibility of a wide variety of items’ packaging, including cosmetics’ packaging, industrial component packaging, tiny tool packaging, and packaging for industrial parts. All of your hanging product packaging, display hole printed packaging, and retail display requirements may be met with the help of our printing solution.

Lining

The lining is a very significant component of packing boxes since it not only helps to protect the item from damage but also enhances the overall quality of the package as a whole. Common types of linings include sponge lining, EVE pearl cotton lining, paper lining, EVA lining, and so forth.

Other types include EVA lining and paper lining. Sponge lining Sponge is inexpensive, pliable, resistant to extrusion, very resilient, and simple to process; all that is required is to cut it with a die.

Special

When it comes to achieving your sales objectives, making sure that the printed hanging display packaging for your retail goods is just perfect may make all the difference in the world. The retail package printers at Corcoran Printing collaborate with customers to provide the most effective display options for their clients’ wares in retail stores. Product packaging with hang tabs and hanging panels may be excellent options for various types of hanging product display requirements.

They are an excellent choice for enhancing the visibility of a wide variety of items’ packaging, including cosmetics’ packaging, industrial component packaging, tiny tool packaging, and packaging for industrial parts. All of your hanging product packaging, display hole printed packaging, and retail display requirements may be met with the help of our printing solutions.

Double side wall

Two layers of corrugated cardboard are placed one on top of the other to create a double wall in double wall cardboard boxes, which are heavy-duty storage boxes. In contrast to the single-walled cardboard box, which does not provide nearly the same level of protection, these boxes include a double layer of cardboard.

Auto bottom

In earlier pieces, we discussed some of the broad trends that have been seen in the commercial packaging business. Today, we are going to shift gears and take a closer look at whether or not auto-bottom packing might be beneficial for your company by analyzing it in further detail.

In order to assist you in determining whether or not purchasing this kind of packaging would be a prudent financial decision, we will guide you through the process of answering eight questions about the requirements of your product and its transportation.

Tray

The auto pack tray packer makes use of a flexible procedure in order to shape the items and load them onto the trays. process with an intermittent motion and four stages that are appropriate for the majority of items. In order to accommodate a variety of speeds, layouts, and items, the Auto pack tray packer is able to be provided with a wide variety of in feeding and grouping choices.

Sealed ends

Folding cartons with side seams and bespoke sizes are called seal-end folding cartons. These types of folding cartons are designed for high-speed setup and filling using conventional carton machines.

Figure 13: sealed ends

Tapered top

a selection of presentation box blanks with tapered tops manufactured from recyclable paper These blanks are provided unglued and flat, ready to be taped or glued. It is made of uncoated print-grade card and is designed for use with offset, ink jet, screen print, letter press, and other printing methods. Produced entirely in the UK with recycled paper sourced from the European Union and the United Kingdom.

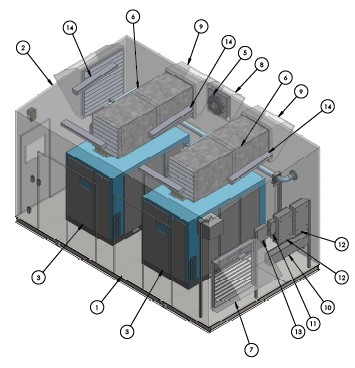

Rooftop

As its name suggests, a rooftop package is a single device that is put on the roof of a building and is linked to the air conditioning system of the structure in order to circulate air throughout the building. The following products are included in this package deal for air conditioning: Evaporator coil, fan, compressor, and condenser in other words, an air conditioner and a chiller are both components that may be found in a rooftop package.

Accordingly, in accordance with the requirements of the roof-top package, it ought to be stated that a single piece or unit is capable of accommodating two primary structures. They also have the capability of being mounted on the ground and providing heating in accordance with the performance criteria of the system. Rooftop packages, as opposed to the splits that are used in residential structures, do not have an evaporator fan and coil that are kept separate from the condenser and the compressor.

Polygonal top

Hinged lid

When you go shopping for takeaway containers, one of the first choices you’ll have to make is whether you want containers that have hinges or containers that do not have hinges. This choice, which is frequently ignored despite having long-term effects, can have an impact on the ease of ordering, the versatility of the product, and its appearance.

Find out more about the distinctions between hinged and non-hinged containers, as well as how to choose the kind of container that is most suitable for your needs.

Flip top

Over the course of many years, Frapak Packaging has been a supplier of plastic flip-top caps. There is a large variety of conventional flip tops that may be offered in standard neck sizes ranging from 20-410 to 28-410, 24-410 to 24-415, and 24-410 to 28-410.

Perforated flip top

When it comes to packing issues, one of the most commonly used boxes is the custom seal end with perforated top box. The top of the box may have a perforation cut into it in the form of an oval, square, or rectangular hole, depending on the kind of opening that has to be created.

Not only tissues, but a wide range of other items can be packaged and sold in these boxes with great success.

The basic principles of carton packaging structural design

Elements

The structure of the packing container is a mix of several elements, including points, lines, surfaces, and bodies. In addition to the parts that have already been stated, the angle is also a very essential structural feature that is present in folding cartons, bonded trays, and corrugated boxes.

Point

There are three different kinds of structural points that can be found in the fundamental structural form of carton packing. These are the multifaceted points of intersection, the points of intersection between two sides, and the points in the plane.

Line

The crease line of the paper package may be separated into two groups according to the adaptation of automated equipment production: the pre-folding line and the working line. Both of these categories are referred to simply as the crease line.

Surface

Due to the nature of the flat sheet used to construct the tray (box), the surface can either be flat or curved.

Body

In accordance with the manner in which paper packaging is formed, the fundamental outline of the construction may be broken down into the following three categories:

- The process of rotational molding Through rotating from a plane to a three-dimensional shape, tube, tray, and tube tray cartons belong to this kind of carton.

- Molding with a shift This kind of carton is comprised of non-tube, non-tray cartons because, during the transition from two-dimensional to three-dimensional molding, the two components of the carton body had to be moved a specific distance apart.

- Modeling in a straight-backwards direction The formation of the body of the paper package using straight-reverse, including the partitions, rear cover, and fixed structure

What is important about packaging structure?

The customer forms their first impression of the product and the brand as a whole based on the packaging. It is imperative that you think about more than just the forms and colors of the packaging when you are considering how to make it more attractive to customers. When it comes to the process of designing packaging, structural design is an essential component.

The design of your product’s packaging should accurately portray your brand and the values it upholds, make your product stand out on store shelves, increase the value of your brand, and provide the end user with a memorable experience when they first open the package. Imagine that you are at the pharmacy store in your neighborhood looking for shampoo.

You always purchase the same brand, but this time you see something that catches your eye: a different brand of shampoo. Since it is created with the exact same components as the other versions, what differentiates this one from the rest? Since it is stored in a more superior container, one would expect it to function more effectively, right? It’s possible that it does, but the packaging that this shampoo comes in is probably the reason you’ve decided to switch to a different brand instead.

The protective properties of packaging structure

To put it more succinctly, protective packaging supplies are materials that are built to protect and buffer a product from potential harm or destruction while it is being shipped or stored. These materials can also be referred to as packaging materials.

On a more technical level, protective packaging can be crafted from a wide variety of materials, including but not limited to cardboard, plastic, metal, and other materials. When packaging a product, protective packaging is frequently used either as the primary component of the packaging or as a secondary form of supply for packaging, depending on the product that is housed within the packaging.

It is useful for a variety of applications; however, the overarching goal of all types of protective packaging is to serve the same function, which is to ensure that a product is delivered in flawless condition, free from any damage or other issues related to shipping.

The convenience properties of packaging structure

Packaging makes it easier to transport a product from one location to another, as well as to stock and use the product after it has been transported. For instance, the new PET bottles of Coke make transporting and storing the product less of a hassle. In a similar vein, the pack of Frooti makes the process of consuming it more convenient.

What is packaging innovation?

No matter what the product is, it will not be able to be used if it cannot be contained, stored, protected, or transported. To phrase it another way, packaging makes it feasible for a product to be used in the manner it was intended. Over the course of history, there has been a tremendous shift toward improved packaging.

Not simply in its appearances and configurations but also, and most significantly, in the roles that it plays. Throughout history, it has evolved in response to changing social systems and the requirements of individual customers. The evolution of packaging functions creates a need for the incorporation of cutting-edge technology into the design of new packages.

How we can present our packaging structure

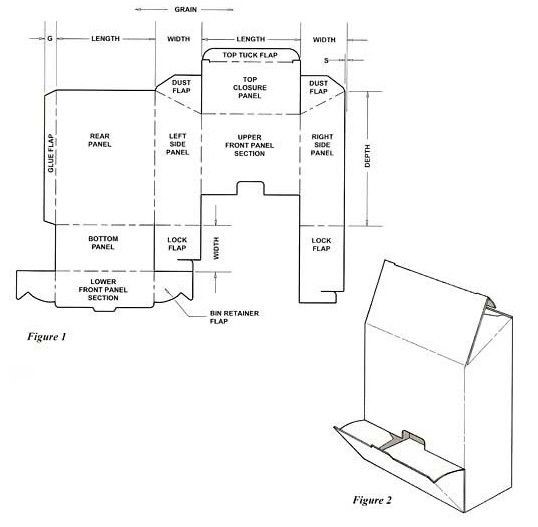

what is packaging dieline and templates

The word “dieline” is often used in the packaging and printing industries to refer to a template that must be used to guarantee that the finished physical product has the right layout. A diagram that indicates all of the folds and cut lines of a package in its flattened state may be created with the help of this template.

Dielines are essential in the manufacturing process of a wide variety of different forms of packaging, including pocket folders, envelopes, boxes, and more. Dielines may be produced by graphic designers, die cutters, or a printer.

packaging mockups

The term “mockup” may have a variety of meanings depending on the sector in which you work. In this session, we will focus explicitly on product design, particularly as it relates to websites and mobile applications.

A mockup is a high-fidelity depiction of the design of your product that demonstrates how the final product will appear. Mockups may be created in the form of images or product models, and the majority of the time, they are produced with the assistance of digital design tools. Mockups are useful for a variety of purposes, including educating stakeholders, demonstrating design suggestions, and promoting products.

3D packaging creator

If you asked many package design teams about the most important industry advances, you’d likely get a range of answers. Digital asset management, structural design solutions, and centralized project management tools are improving package design for firms worldwide. Companies know that packaging attracts buyers when products are on the shelf.

Due to the growing number of companies trying to stand out in a competitive market, this industry has made great strides. Three-dimensional packaging design is one of these innovations. 3D packaging design solutions have several benefits, which will show why this phase in package design is so crucial. Let’s first explore why firms need product packaging.

3D modeling

The presentation of the design of the packaging via the use of 3D modeling is becoming more popular since it enables the brand to create photos very rapidly without the need to first set up the full scene for a photo shoot of the packaging. Once the 3D model has been generated, it may be utilized across a variety of channels, including digital media, e-commerce sites, websites, marketing material, and so on.

How we can design a very good packaging structure?

It’s also crucial to the supply chain’s efficiency. To achieve a functioning package and a successful packaging production run, open communication must be maintained throughout the packaging design process. Brands that outsource their package manufacturing must communicate with designers, who may not have the printing experience to comprehend how their packaging idea is generated or whether it can be mass manufactured.

Of course, “excellent package design” is a huge issue, especially considering the many purposes packaging performs for numerous departments and across the packaging supply chain. “Good package design” is crucial. This study focuses on the aesthetics of well-optimized and designed packaging.

Depending on your packaging design skills, these dos and don’ts may seem obvious or shocking. This essay aims to highlight the importance of carefully considering how package images affect customers, producers, shippers, and everyone else who interacts with packaging at any point in its existence.

How we create value?

Due to its impact on commodity flow, it is also vital to supply chain efficiency. To achieve a functioning package and an effective packaging production run, communication must be open throughout the packaging design process. Open communication throughout package design may achieve this. Brands that outsource their package manufacturing must communicate with designers, who may not have the printing experience to comprehend how their packaging idea is generated or whether it can be mass manufactured.

Designers must grasp how their package idea is manufactured to connect with printers. “Excellent package design” is a huge problem in and of itself, but when you consider the many purposes packaging serves for various departments within the organization and throughout the packaging supply chain, it becomes even more important.

“Excellent packaging design” is very important. Because of this, this study focuses on a single streamlined and high-quality package design element, the visuals. The following criteria for creating a box may appear obvious or alarming, depending on your package design experience.

This article aims to highlight the importance of carefully considering how package images affect customers, producers, shippers, and everyone else who interacts with packaging throughout its existence. This is because we want this post to highlight how important package images are to customers.

Getting noticed and telling stories

Packaging is crucial to marketing since it’s the first thing customers see. Its design and graphics attract clients. In previous articles, we emphasized how crucial genuine packaging is for marketing and how an inventive and beautiful design is no longer enough.

This remains a popular misperception. User satisfaction is key. Because of this, firms and designers are expanding packaging’s range of action by combining it with other powerful marketing methods. One of the methods is storytelling. It can engage the audience. The box’s design conveys a story. Packaging that tells a story may boost sales since people enjoy stories.

Storytelling engages customers by evoking memories, experiences, and feelings. It’s succinct, ensuring brand recall. Knowing the brand’s history, beliefs, and people will help them connect with customers more than any other marketing strategy.

They can build relationships with those consumers. Storytelling improves marketing. They stimulate our inner child and make us feel welcome since they remind us of our childhood. They stimulate us to buy.

Reducing costs and optimizing performance

Cost optimization is a discipline that is continuously practiced with a business-centric orientation with the goal of reducing expenditures and costs while increasing overall company value.

Improving costumer experiences

When it comes to the topic of packaging, making a decision on the container that your product will be stored in is just one of many considerations among many others. In fact, the decisions you make about anything from the colors and typefaces to the actual material itself will have an effect on how customers evaluate both your brand and the goods you sell.

The design of the product’s packaging may, in addition to effectively expressing what the product is, what it accomplishes, and who it is for, also appeal directly to what your target audience is searching for in a product of its kind. Packaging that has been thoughtfully designed may influence whether a buyer chooses your product or one of your competitors’, and it can also enhance the whole shopping experience for the customer.

Reducing impact and going circular

If you want to be sure that your new package design has the least possible effect on the environment, you should think about the product over its full lifespan. When it comes to the redesign of your packaging, you may want to solicit the expertise of other companies involved in your supply chain.

Enable digital transportation

A look at how some of the most successful firms in the paper and packaging industry are meeting the problems posed by the transportation sector to the uninitiated, it would have seemed as if the paper and forest products sector was about to go out of business.

There are fewer and fewer fliers being sent to people’s mailboxes. Newspapers are transitioning to digital formats or going out of business. By the time more and more individuals are keeping their libraries on e-readers like the Kindle. The fast digitization of the so-called “print” media has, without a doubt, had an impact on the industry. This is just one facet of the whole picture.

According to research conducted by McKinsey & Company, the market for paper and other goods derived from forests is continuously expanding. Both the demand for hygiene products made from pulp and the demand for packaged goods are increasing all over the world as a direct result of the increasing prevalence of online shopping.

This development has had a significant influence on the way businesses in this field function. As a result, many of them have been forced to reorganize their facilities and the procedures they follow. Even while these shifts have brought about new difficulties, they have also brought about a wealth of new possibilities, particularly in the transportation sector.

Conclusion

Structural package design refers to three-dimensional package that uses creativity and industrial design to create an enjoyable user. Structural package design should make your product stand out on store shelves. It can increase brand value, and give customers a memorable unwrapping experience.